Production and Packaging of Wet Wipes and Swabs

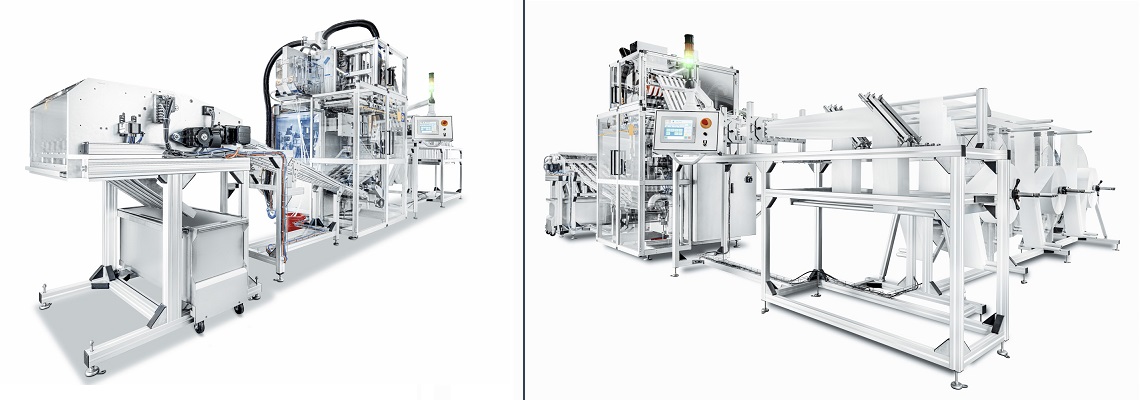

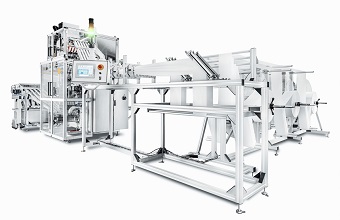

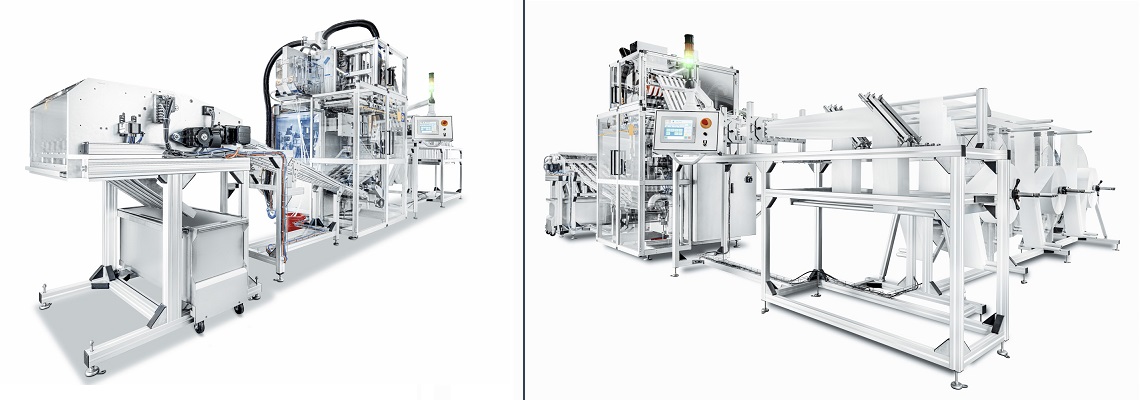

4-Side-Seal Sachet Machine FB-S (ATEX) incl. Production of Disinfectant Wipes

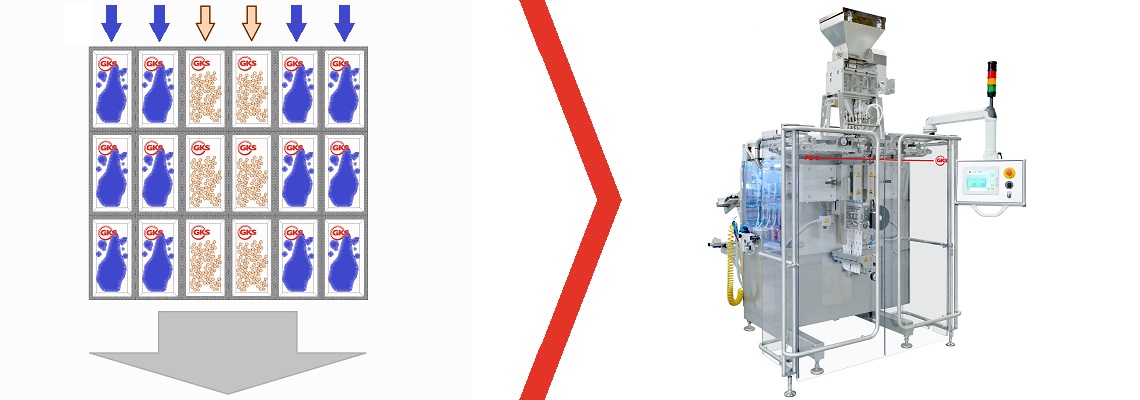

A special upgrade of our four-side-seal sachet machines are the multi-lane production and packaging of sachets including liquid dosing in four-side-seal sachets.

This upgraded equipment can be used, for example, to produce folded disinfecting or cleaning wipes and a variety of swabs.

Variants / Options

- explosion-proof version (ATEX)

- removal of the sachets by means of a spreading belt conveyor

- multi-lane stacking station for sachets